Our products and services

Industrial maintenance services and transmission products

We service process equipment on site or at our service centres, and procure or manufacture all spare parts needed for the maintenance. If necessary, we modify and update serviced equipment with modern solutions.

We provide our customers a maintenance report with photos for all work performed and recommendations for follow-up measures if necessary. We grant a warranty for all equipment we service.

Examples of equipment we service routinely and with professionalism

- Industrial gears and gear motors

- Industrial pumps

- Mixers

- Sorters

- Screws and clamps

- Rotary feeders

- Axles

- Various fans

- Compressors

- Tensioners and actuators

- Shutdown maintenance

Our Products and Services

We service process equipment on site or at our service centres, and procure or manufacture all spare parts needed for the maintenance. If necessary, we modify and update serviced equipment with modern solutions.

We have had a co-operation agreement with Kumera Drives Oy since 2017 and our service centers are part of Global Kumera service network.

KTT Tekniikka offers all the necessary support for field maintenance. Our field maintenance experts are also skilled in more demanding equipment installations, alignments and problem solving. We are flexible and always try to help even in unforeseen emergency situations.

Our service also includes support for the planning of maintenance, renovations, modernizations and necessary measurements.

We provide condition monitoring and endoscopy imaging of process equipment. Our services includes a comprehensive range of measurements of gears and bearings, for example. We also perform acceptance inspections.

For 3d measuring we operate with portable Hexagon Absolute Arm 8725 articulated arm measuring device.

We provide parts and components for process equipment either as OEM or equivalent parts, depending on our customers’ choice. Spare parts for a wide range of applications from the world’s leading manufacturers.

We stock and deliver components for customer and device-specific needs.

Products for power transmission

- Gears – Kumera

- Motors

- Couplings – Jaure and Samiflex

- Sealings

- Bearings

- Spare parts and components

We design solutions from individual components to complex assemblies. We carry out our customers’ projects from equipment assemblies to individual, customer-specific specialised products.

We offer a comprehensive service from pre-design to implementation and warranty service. If necessary, we will take care of the operability of equipment throughout their lifecycle.

Services

- Modifications and development of existing operational constructs

- Prototype design

- Changes in use

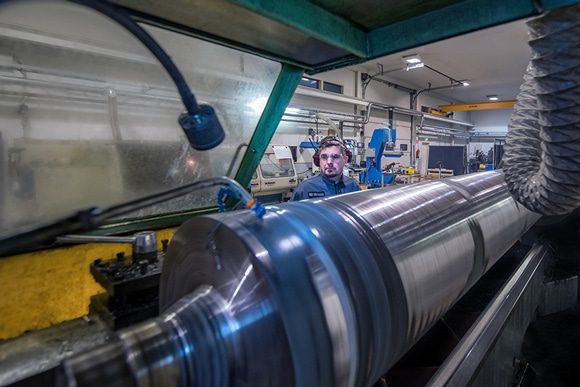

We perform machining work of individual parts, urgent deliveries, repair machining and standard products for assembly and manufacturing. Our service also covers titanium welding and machining in our own workshop or at customer sites. We offer e.g. repair turnings for sealing surfaces, threads and sleeves. We turn small series such as axles, bushings, pulleys, bearing housings, labyrinth housings and rings with CNC machines.

Services

- Boring

- CNC machining

- Lathe work

- Welding

- Coatings

- Other machining methods

Companies we represent in Finland

Do you need help with components and maintenance services?

Contact our sales and technical support!

Contact details

KTT Tekniikka Oy

Sepänkatu 2

48770 Kotka

Email: ktt@ktt.fi