Engineering workshop services

Our own engineering workshop ensure fast and reliable service

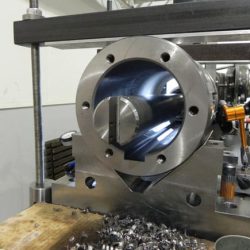

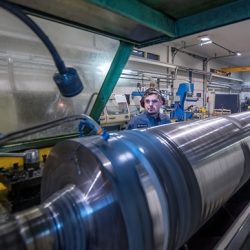

We perform machining work of individual parts, urgent deliveries, repair machining and standard products for assembly and manufacturing. Our service also covers titanium welding and machining in our own workshop or at customer sites.

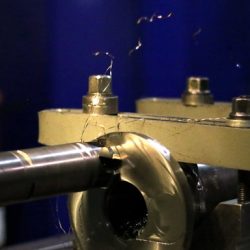

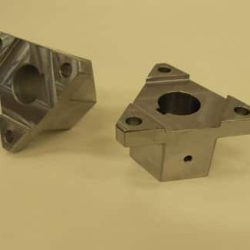

We offer e.g. repair turnings for sealing surfaces, threads and sleeves. We turn small series such as axles, bushings, pulleys, bearing housings, labyrinth housings and rings with CNC machines.

Services

- Boring, Y=1200, X=1600, Z=1250, max 3500kg

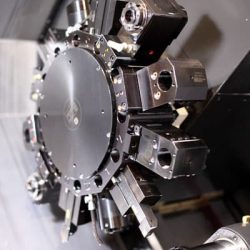

- CNC machining

- Lathe work

- Welding

- Coatings

- Other machining methods

- Wedge grooves with a draw bench or planer

- Milling and grinding

- Diamond coating of parts

Examples of our standard works

Diamond coating has good wear resistance, lower friction and chemical resistance when it is necessary to replace materials such as titanium. Parts that can be coated include sealing sleeves, shafts, blade pieces, impellers and side plates. Welding work at our workshop or on the customer’s premises (qualifications in black, mixed joint, acid resistant, duplex and super duplex)

- Inspections and possible repairs of gear bearing positions

- Boring of grinder chambers for larger blades

- Feeder drill and rotary feeder frame machining after repair welding

- Mounting beds and trestles

- Wedge grooves with a draw bench or planer

- Milling and grinding

- Diamond coating of parts

Pictures of our works

Do you need help with components and maintenance services?

Contact our sales and technical support!

Contact details

KTT Tekniikka Oy

Sepänkatu 2

48770 Kotka

Email: ktt@ktt.fi